How to make clothes step by step

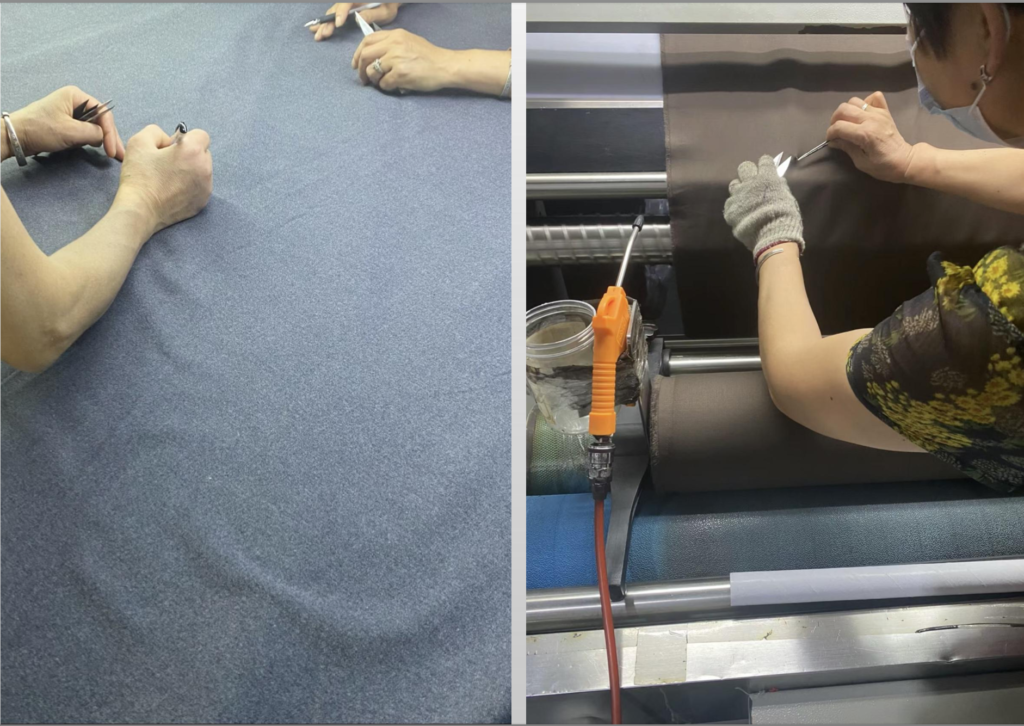

#1 Fabric inspection

Fabric inspection process and standards

Fabric inspection process

We have strict quality inspection process from yarn to finished fabric. Including confrimation of color of hand loom samples and lab dip samples.

Fabric inspection standards

We strictly inspect fabrics in Standard Test Methods For Visually Inspecting AndGrading Fabrics (Four-point system). And every piece of fabric that has been inspected will have an inspection report.

#2 Sample clothes inspection

Sample clothes inspection process

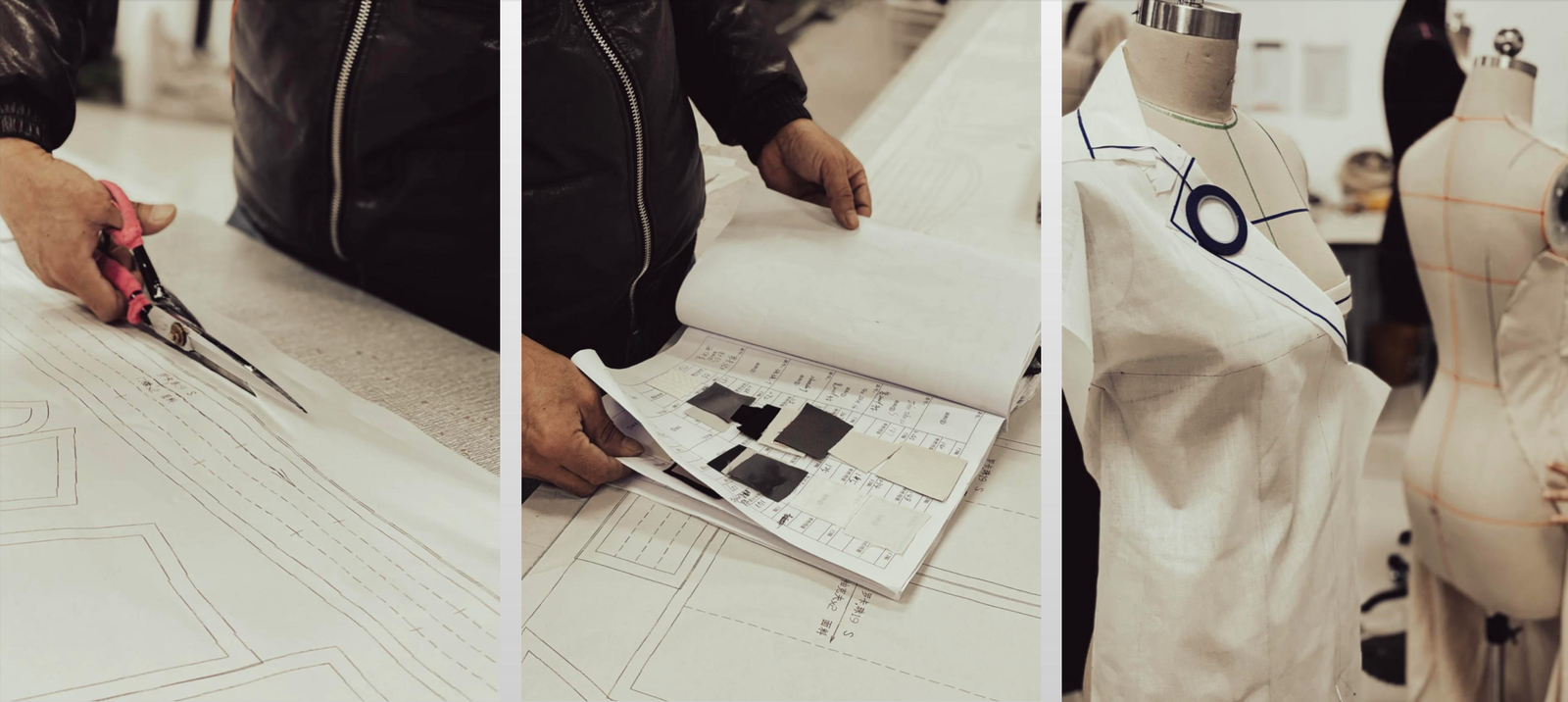

After receiving the TPKs, the production department will immediately check the information to see if there are any special processes such as embroidery and printing. And optimize paper patterns to achieve customer design effects while reducing costs.

After checking, the production department arranges for the fabric department, accessories department, embroidery and printing factory, and sample room to arrange samples.

The fabrics and trims department immediately looks for fabrics and trims of the right quality and color.

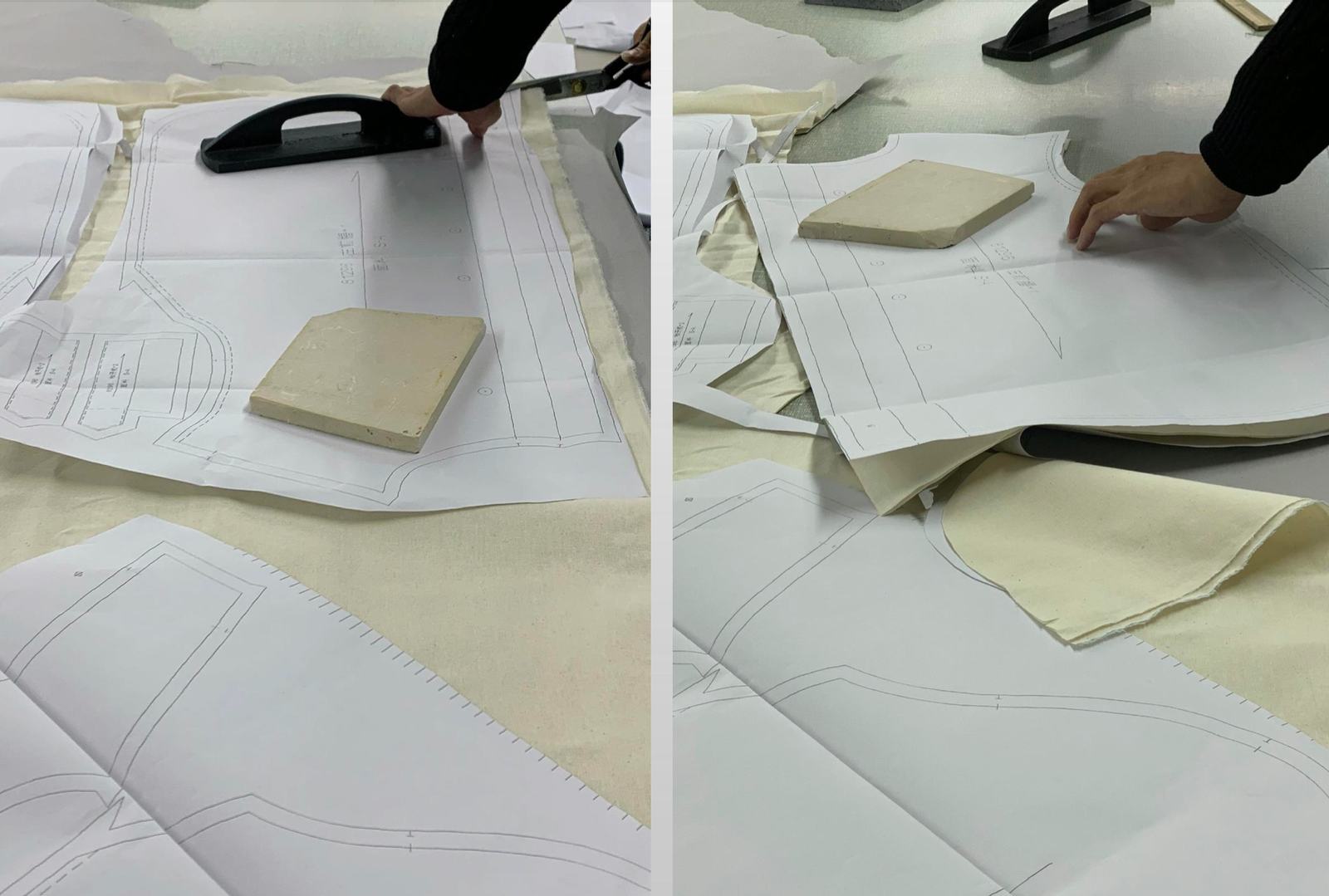

The pattern makers make paper patterns according to the requirements. If he finds that the size is unreasonable, we will immediately make suggestions to our customers and confirm with them.

Confirm printing and embroidery samples

Check the quality of fabrics and accessories, and send them to the sample room if there are no problems.

After sample room receives the fabrics and accessories, they will check the TPK and quality again.We’ll start making samples if there is no problem.

After receiving the fabric, sample makers will wipe the machine clean and adjust the equipment. For softer fabrics such as silk, we will use No. 7 ball- head needles imported from Japan and put on white gloves to start production.

After samples are sewn, we will iron them. The ironed garments will be hung on hangers and sent to the technical department.

The technical department once again checks the model’s fitting results based on the customer’s TPK. If there are any suggestions, they will be written on the sample card and the opinions will be given after customers try them on.

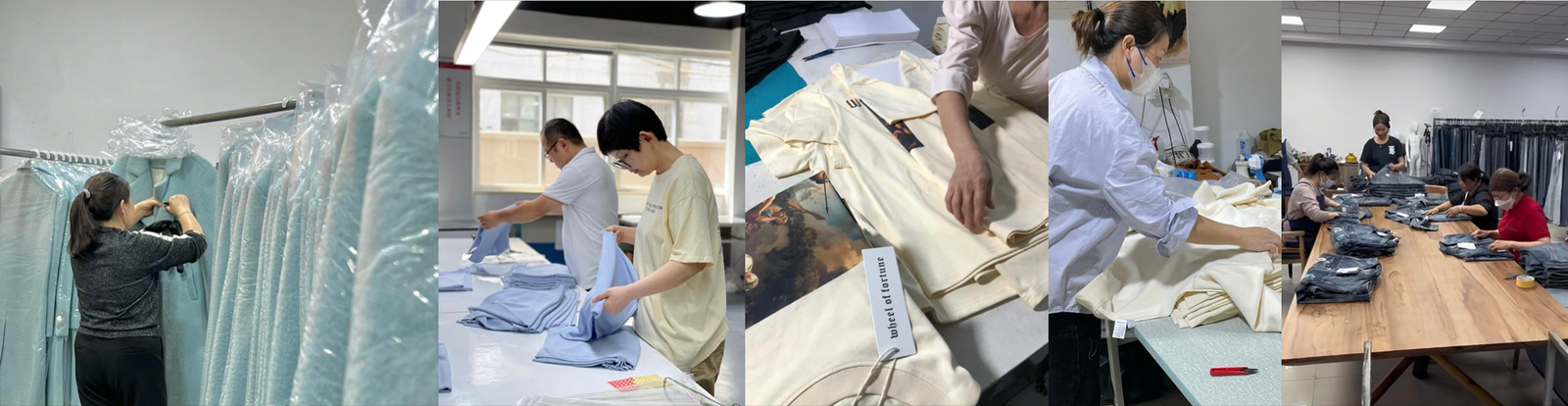

The samples will be packed with soft tissue paper. If there are zippers, buttons and other metal or hard accessories, we will wrap them in a full circle with tissue paper separately.

The packaged sample garments will be accompanied by detailed measurement records and samples suggestions to the salesperson, who will check again and send them to customers

#3 Bulk inspection

Bulk inspection

We adopt the principle of three-party inspection and joint responsibility to ensure that the quality of goods can be effectively controlled.

Inspect the first piece of PPS and submit the inspection report. Only after confirmation can the factory arrange mass production.

QC conducts quality inspections in three stages and conducts inspections piece-by-piece after mass production is completed.

After receiving the inspection report from QC, the merchandiser needs to conduct random

inspection again before shipping. Only if the random inspection is correct can the shipment bearranged.

Bulk inspection

We have our own QC and QA for checking goods, and we use piece-by-piece inspection method to inspect bulk order. After receiving the order information, QC will first carefully check whether the information is complete and accurate, and check whether the last pre-production sample has been confirmed by the customer. After confirming that there are no doubts about the fabrics and accessories, check embroidery, printing, washing method and other production factors, and understand the customer’s special requirements, then proceed to the following products control process:

We strictly implement piece-by-piece inspection method to ensure that each customer no worries about quality issues when receives products in bulk.

The pre-production meeting for bulk order production in the factory will be held as soon as possible: QC, team leaders, workers, inspectors, etc. will hold pre-production meetings in advance in order to inform everyone of the precautions for each style and the different requirements.

QC strictly implements initial inspection, in-line inspection and final inspection.

Initial inspection: first-piece inspection of bulk goods. Our company believes that the inspection and confirmation of first-piece products is very critical. When it is still the initial stage of bulk production, if problems can be discovered at this time and corrected in time, they will not affect the bulk and delivery time. This can also avoid and reduce rework rate after finished product. When the first product comes out, QC will check the following steps:Check the style;

Check sewing workmanship;

Measure the garments size;

Report the inspection results of the first product (pre-production sample report)

In-line inspection: When about 10% of the finished product comes out of the factory, our company will conduct a in-line inspection of the product to check whether the quality is qualified. During the quality control process, quality problems are discovered in a timely manner and suggestions for improvement are made to ensure that the problems are effectively solved and the production line progress is continuously tracked and quality status to ensure stable and reliable product quality.

Final inspection:QC will conduct final inspection again on a proportional basis and perform functional testing.

Zipper test: Test whether the zipper pulls smoothly without jamming or falling off.

Button test: Check whether the button is firm, whether the buckle is tight, and there is no looseness.

Other functional tests: According to style requirements, conduct other functional tests such as waterproof,

breathable, wear-resistant, etc. to ensure that the product meets the standards and requirements.

Through the above detailed inspection process, the quality of clothing products can be effectively controlled to improve customer satisfaction. QC will ensure that every step of the operation and make sure the quality is up to standard before issuing a written inspection report. The saleman can only ship the goods after receiving the inspection report.